What Does Premier Aluminum Llc Mean?

What Does Premier Aluminum Llc Mean?

Blog Article

Some Of Premier Aluminum Llc

Table of ContentsNot known Factual Statements About Premier Aluminum Llc Getting The Premier Aluminum Llc To WorkAn Unbiased View of Premier Aluminum LlcMore About Premier Aluminum LlcSome Known Questions About Premier Aluminum Llc.

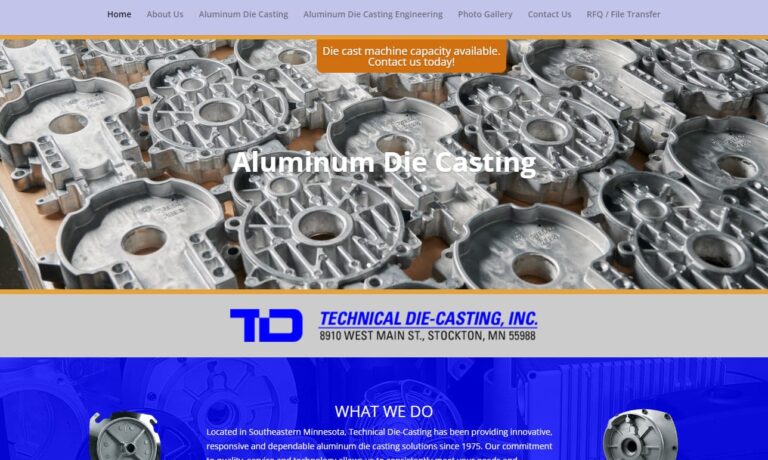

When selecting a light weight aluminum shop for your production demands, it's important to study several variables. Among one of the most critical aspects to consider is the experience and competence of the foundry. Selecting a foundry who has the best understanding of the light weight aluminum spreading procedure, and the portfolio to show for it, helps to have a successful outcome for your task.Having the experience and industry expertise to craft your spreadings for optimum manufacturing and high quality end results will certainly simplify the task. Making aluminum spreading calls for a facility set of processes to attain the appropriate outcomes. When choosing a brand-new light weight aluminum factory to partner with, ensure they have substantial sector experience and are well-informed concerning all aspects of the aluminum casting procedure: layout, production, material analysis, and item screening.

The factory must additionally have a tested track record of providing extraordinary products that meet or surpass consumer assumptions. Quality control must additionally be at the top of your checklist when choosing a light weight aluminum foundry. By collaborating with a qualified shop that complies with the criteria for quality assurance, you can shield the honesty of your item and guarantee it fulfills your specs.

The Facts About Premier Aluminum Llc Uncovered

Different parts that extremely complicated forms can be produced using this process. Before you start browsing for a reliable light weight aluminum die caster, there are some important things that you require to do.

You have to ask on your own what type of light weight aluminum die castings you need. After determining what you need, you have to state the requirements of the aluminum pass away castings you require. Identify the weight, density, dimension, and various other specifications of the light weight aluminum die-cast you call for. It would additionally be far better if you can attract and show all the dimensions of the aluminum die-cast.

Do you know just how much money you have to spend on the products? In order to do this, the very best point to do is to establish the number of light weight aluminum diecasts you need. After having this information, you can begin investigating light weight aluminum die-casting producers. You can do this by just typing the keyword phrase" Aluminum die casting makers" on the Google online search engine.

Some of the questions you need to ask on your own are whether they have actually experienced and trained operators, how long their service has actually functioned, or if they have some achievements. You can commonly get the solution to these questions from the manufacturer's site. You can research other web sites or exterior sources to validate if the info given on the producer's internet site is authentic.

Premier Aluminum Llc for Dummies

Another point you have to take into consideration is the producer's capability to create aluminum die-casting items. To put it simply, the quantity of products the maker can produce at a given time. Some of the crucial concerns you require to ask yourself are whether the producer can create a greater volume or can the producer meet your demands.

(https://www.edocr.com/v/0onvglma/garymartin53403/premier-aluminum-llc)What if your firm calls for 10,000 pieces of certain device parts from the producer within one month? You got this amount; however, the manufacturer can only generate 5000 pieces of these device parts within one month (Casting Foundry). Consequently, you will not have the ability to obtain the quantity that you buy on schedule

Not known Facts About Premier Aluminum Llc

It is essential that you need to make inquiries if the manufacturer is carrying out an in-house tooling procedure. In addition, you need to ask the maker just how much the price of internal tooling is. The internal tooling process, which permits you to create unique designs and shapes can be an extra price.

This element directly associates with the supplier's production capacity. Aluminum Metal casting. You have to look special info for a producer that can make certain quicker delivery of products.

This means that there are numerous alternatives that you can select from. Today, consumer needs keep altering. It appears that consumers are looking for an excellent combination of quality, cost-effectiveness, and sturdiness. That is why it is significantly recommended that you need to select a maker that can create different types of light weight aluminum die-cast products.

The smart Trick of Premier Aluminum Llc That Nobody is Talking About

The majority of often, these light weight aluminum die-casting products will certainly call for some decors, machining, or completing touches. Having this in mind, you should search for a maker that can implement a range of secondary ending up works as soon as die casting is done. Some examples of completing operations consist of Chromating, CNC Machining, Sandblasting, Powder covering, Anodized, E-coating, Damp painting, Plating, and much more.

Die casting is one of the most affordable, accurate, and protean production procedures in the world minute. The process includes fitting molten essence, under stress, into an applicable die (planet), and previously strengthened it can be ejected and finished (if required) in a range of methods. Report this page